STAINLESS COIL

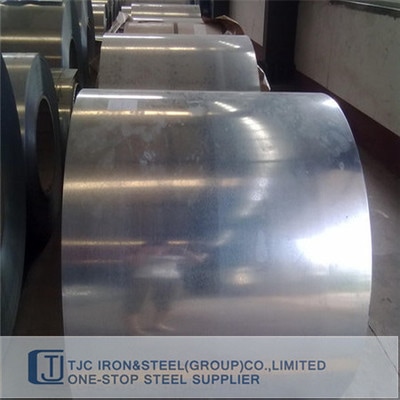

Stainless Steel Coil's surface is bright and clean,it is with higher plasticity,toughness,and with anti-acid,anti-alkali's properties.

Stainless Steel Coil's production ways are divided into Hot Rolled and Cold Rolled,which including 0.02-4mm's Thin-Cold-Rolled Stainless Coil and 4.5-50mm's Hot-Rolled-Stainless Coil.

According characteristics of different grades,there are austenitic,ferritic,martensitic,austenitic-ferritic and duplex stainless coil.

There is a request for stainless to afford corrosion of oxalic acid,ferric sulfate sulfuric acid,nitric acid,nitric hydrofluoric acid,copper sulfate sulfuric acid, phosphoric acid,formic acid,etc.Stainless coils are widely used in chemicals,foods,medicine,paper making,

petroleum and atomic energy's industries and building,kitchenware,car and home appliances' spare parts.

In order to keep stainless' yield strength,tensile strength,elongation and hardness meeting requested level,it is necessary to take annealing,solid solution,aging and other relevant heat treatments to the stainless coil

Stainless coils' property of anti-corrosion depend on its alloy composition(Cr,Ni,Ti,Si,Al,Mn,etc) and internal structure,which Cr is the main element for such effect.Cr is with high chemical stability,and can form passivating film on the surface of coil,which can make the stainless segregate from air to keep away from oxidized.This can improve the property of anti-corrosion of stainless.

Stainless Coil's Name:

1.200 Series Stainless Coils (201,201L,201LN,202,204),Austenitic Stainless

2.300 Series Stainless Coils (301,301L,301LN,302,304,304H,304L,304LN,304N,305,309,309H,309S,310,310S,316,316L,316LN,316N,

317,317L,321,etc),Austenitic Stainless

3.400 Series Stainless Coils (405,409,410,410S,429,430)

4.Duplex Stainless Coil (S31803,S39274,S32950,S32906,S32760,S32520,S32506,S32101,S32003,S32001,S31260,S31200,

S32900,S32304,S32205,S32750,S32550)

Stainless Steel Coil's production ways are divided into Hot Rolled and Cold Rolled,which including 0.02-4mm's Thin-Cold-Rolled Stainless Coil and 4.5-50mm's Hot-Rolled-Stainless Coil.

According characteristics of different grades,there are austenitic,ferritic,martensitic,austenitic-ferritic and duplex stainless coil.

There is a request for stainless to afford corrosion of oxalic acid,ferric sulfate sulfuric acid,nitric acid,nitric hydrofluoric acid,copper sulfate sulfuric acid, phosphoric acid,formic acid,etc.Stainless coils are widely used in chemicals,foods,medicine,paper making,

petroleum and atomic energy's industries and building,kitchenware,car and home appliances' spare parts.

In order to keep stainless' yield strength,tensile strength,elongation and hardness meeting requested level,it is necessary to take annealing,solid solution,aging and other relevant heat treatments to the stainless coil

Stainless coils' property of anti-corrosion depend on its alloy composition(Cr,Ni,Ti,Si,Al,Mn,etc) and internal structure,which Cr is the main element for such effect.Cr is with high chemical stability,and can form passivating film on the surface of coil,which can make the stainless segregate from air to keep away from oxidized.This can improve the property of anti-corrosion of stainless.

Stainless Coil's Name:

1.200 Series Stainless Coils (201,201L,201LN,202,204),Austenitic Stainless

2.300 Series Stainless Coils (301,301L,301LN,302,304,304H,304L,304LN,304N,305,309,309H,309S,310,310S,316,316L,316LN,316N,

317,317L,321,etc),Austenitic Stainless

3.400 Series Stainless Coils (405,409,410,410S,429,430)

4.Duplex Stainless Coil (S31803,S39274,S32950,S32906,S32760,S32520,S32506,S32101,S32003,S32001,S31260,S31200,

S32900,S32304,S32205,S32750,S32550)